microstations meet Uganda

In 2018, when Andy, Aggrey, and Jason started Zombo Coffee Partners Ltd, they envisioned a future that offered a solution for the three main problems farmers face in the Zombo region: lack of infrastructure, poor quality, and no access to the market. Andy, the founder and designer of the micro-station model and of Zombo, thought a future in which farmers become independent is possible. He has been working to prove this since.

By offering an above-market cherry price to farmers and paying a bonus for quality, c-price freedom can be achieved; by providing technical and processing assistance, quality can get better and stabilize. Andy Carlton's strategic system has helped farmers over the past years to improve the quality and consistency of their coffee; together with his long-term business partner Aggrey, they've been supporting farmers to become economic actors in their own right by owning and running the micro stations. Livelihood in this neglected region of the world is beginning to improve, and farmers are now projecting a future for their children's education.

Zombo operates in one of the country's poorest regions in the West Nile. The farmers, mostly Alur people, grow most of their own food and have a hundred coffee trees in their fields. Before Zombo, however, coffee was something like a cash machine for most farmers. They still needed to see what improving quality could offer them. Or, as Aggrey puts it: "Farmers used to look at coffee as something falling from their trees. They used to only look at coffee when the season came."

Over the past years, results have started to spread and manifest. Zombo has managed an exponential price increase and solid growth. But, sadly, large exporters are all too aware of this situation, and when they heard that Zombo was paying higher prices and making farmers co-owners of their company, they decided to outbid them. What will happen when they force Zombo to close down? They can return to their usual practice of squeezing farmers with shamefully low prices and no competition.

Our job, and that of the partners we introduced to Zombo, is to not let that happen…

-

DescripUganda is already well-known for excellent robusta coffee. In recent years Uganda has begun to build a second reputation, as an origin of fine arabica coffees. Fertile land, volcanic soils, plentiful rainfall and sunshine, good varietals, diverse pockets of suitable micro-climates and altitudes, all combine with improved production practices to contribute to this emerging origin of really tasty specialty coffees.

The Zombo region, the Alur Highlands, is for most coffee people a blind spot on the map. It is located on the western banks of the Nile, the river that leaves Lake Albert and starts its long, meandering journey to the Mediterranean. On this hilly plateau, the Alur people speak a Nilotic language which is not related to the majority Bantu languages of sub-Saharan Africa. They have strong cross-border family relationships in DR Congo, next door.

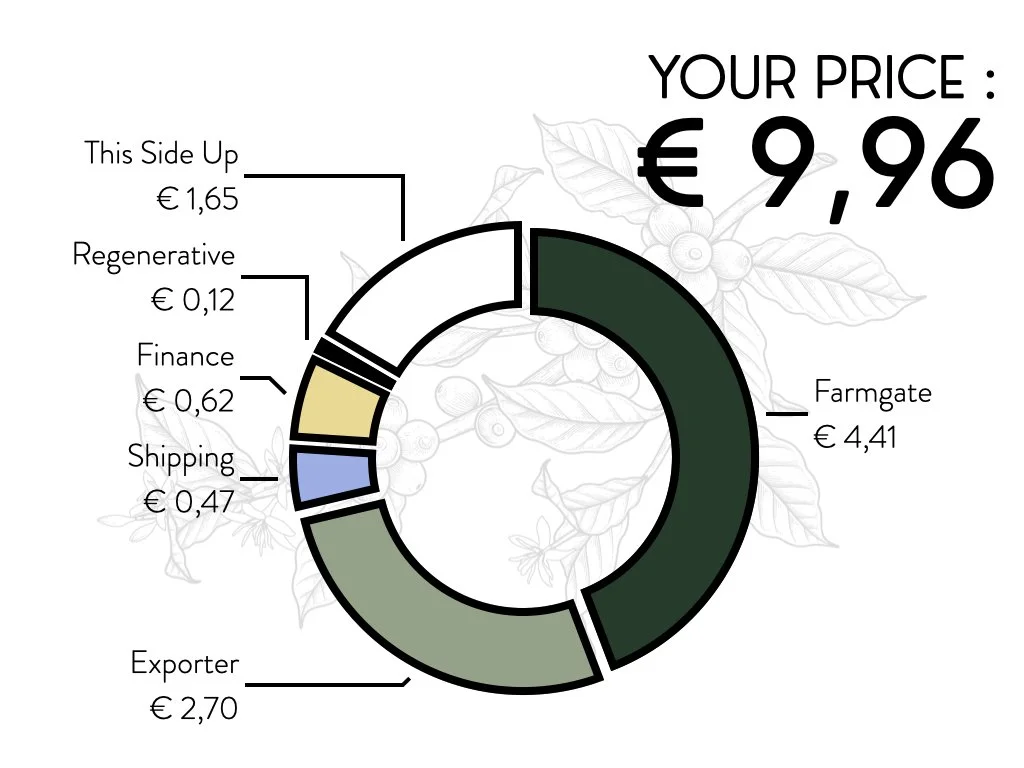

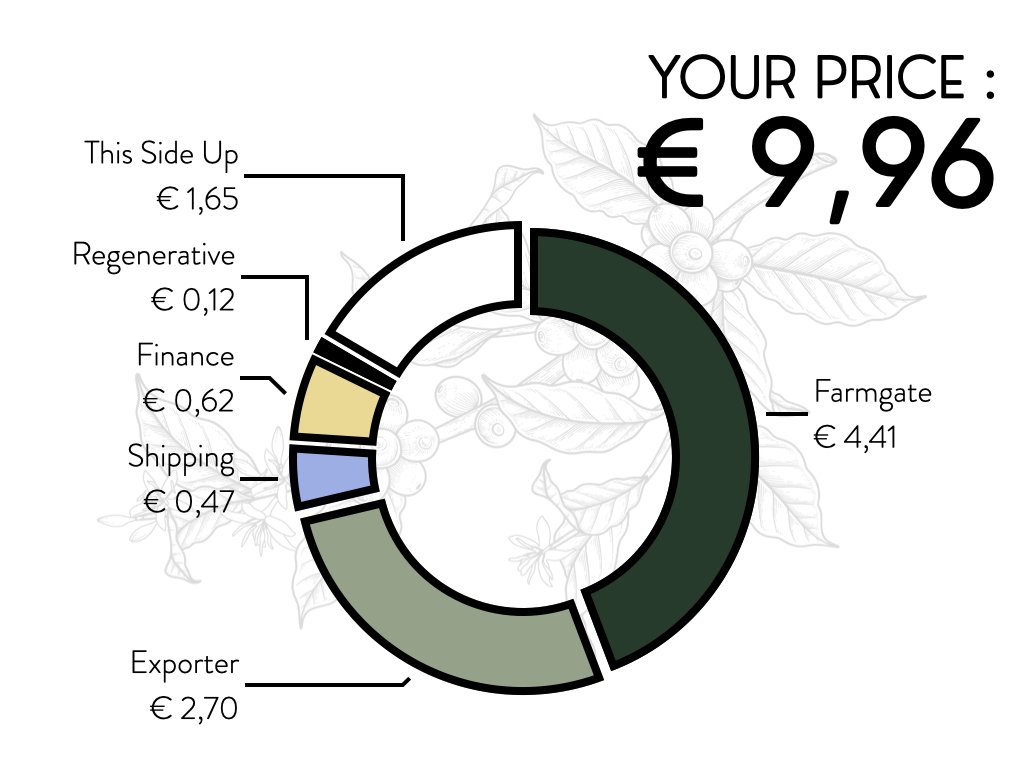

Zombo Coffee Partners is pioneering an innovative business model, a unique African hybrid that combines a private shareholder company with a group of smallholder cooperatives by offering the coops shares in the company. Zombo works in close partnership with the coops, helping their members to add value by improving quality, and sharing profits with them when we sell their coffee, all with a mindset and focus of full price transparency and open book keeping. Next to all this, Zombo has a strong focus on helping the farmers to break free of the C-price trap for coffee as a commodity, a mission that lies very close to the heart of This Side Up.

This is the original document Andy wrote in 2016 about how the microstation concept developed. tion text goes here

These are the microstations Zombo brought together for the 2023-2024 harvest.

We work with all microstations that Zombo works with.Also, we buy a lot called “Jukia Hill”,

this is the coffee from farmers close to Zombo’s dry processing plant, Jukia Park.

Traceability

You can find all the signed contracts and shipping documents that we made with Zombo since 2021 below (Google Drive).

2018: Became friends with Aggrey and Andy of Zombo Coffee Partners within weeks of their company starting.

2019: Bought our first Zombo specialty coffee, from micromills Ajere (then called “Atyenda”) and Culamuk.

2020: Started discussing the C-Price Freedom concept – getting away from New York’s mad roller-coaster. This Side Up worked with four microstations, being Culamuk, Ajere, Gonyobendo and Ndhew. Next to these “single microstation coffees”, the peaberry was a blend of six microstations, the other two being Ayaka and Ambe.

2021: Zombo paid a floor price of 60 USD cents per kg of fresh cherry for the first time. thanks to the support from two donors, The Royal Dutch Embassy in Kampala and Irish Aid, channeled via Oxfam Uganda, two new farmer groups were created this year: Mitapila and Ayanyonga. Their coffees came with amazing results: Mitapila stood out with scores around 86 for both the fully-washed and the women’s natural coffees. Ayanyonga’s scores were only slightly below, around 85

2022: Farmers were paid the highest prices ever for their fresh cherry – we visited some of the coffee microstations.

2023: The Futureproof Coffee Uganda project started – bringing regenerative agriculture to the Ugandan north-west, courtesy of This Side Up customer Wakuli and the Dutch government.